The disk I will be using is:

12" diameter 1/2" thick G-10 fiberglass laminate. 8 - 1/2" diameter pure tungsten electrodes Top speed 4000 rpm which equals 533 BPS, way more than I anticipate using.

G10 Fiberglass: http://matweb.com/search/SpecificMaterial.asp?bassnum=PGLAM04

Tungsten: http://matweb.com/search/SpecificMaterial.asp?bassnum=AMEW000

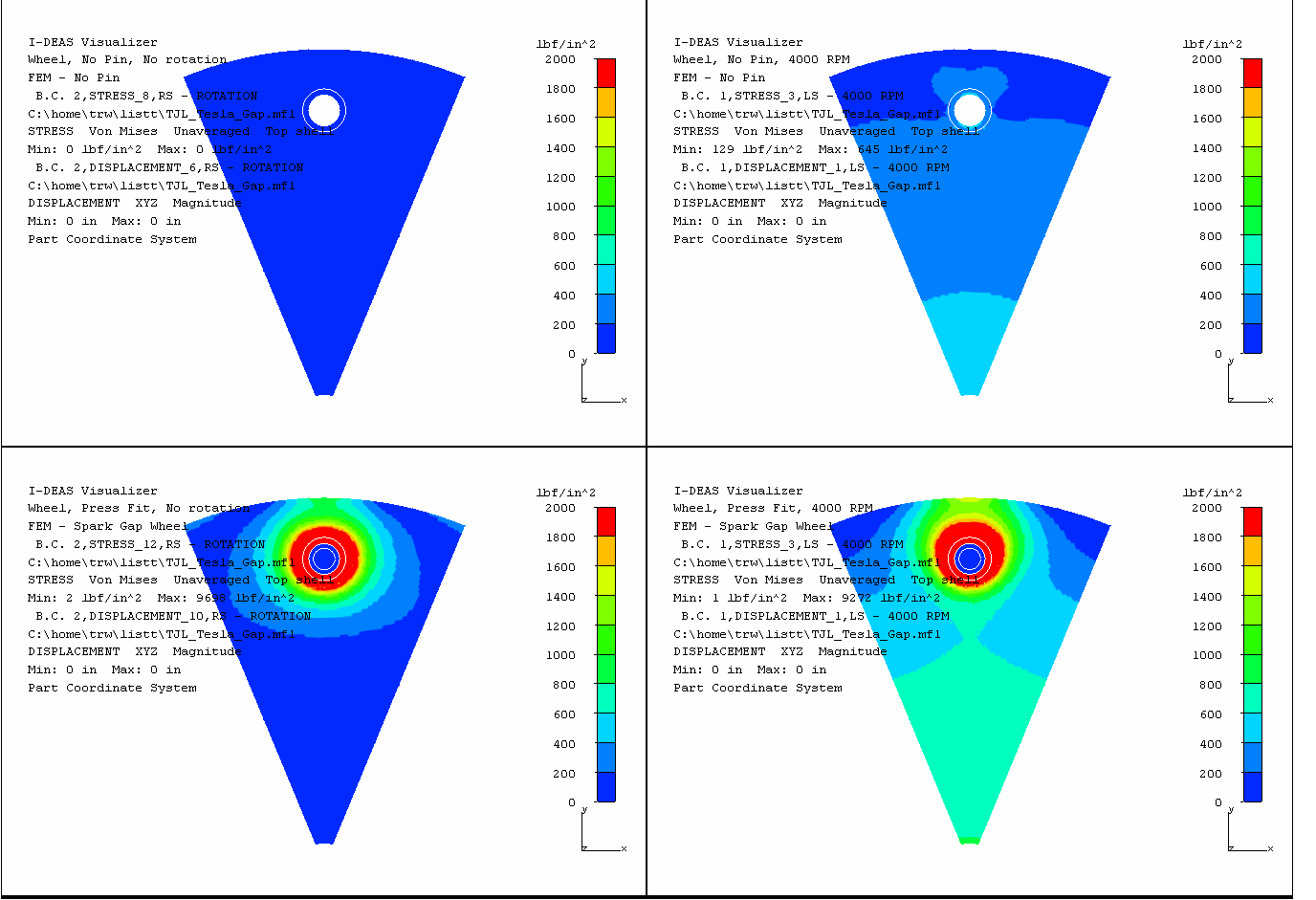

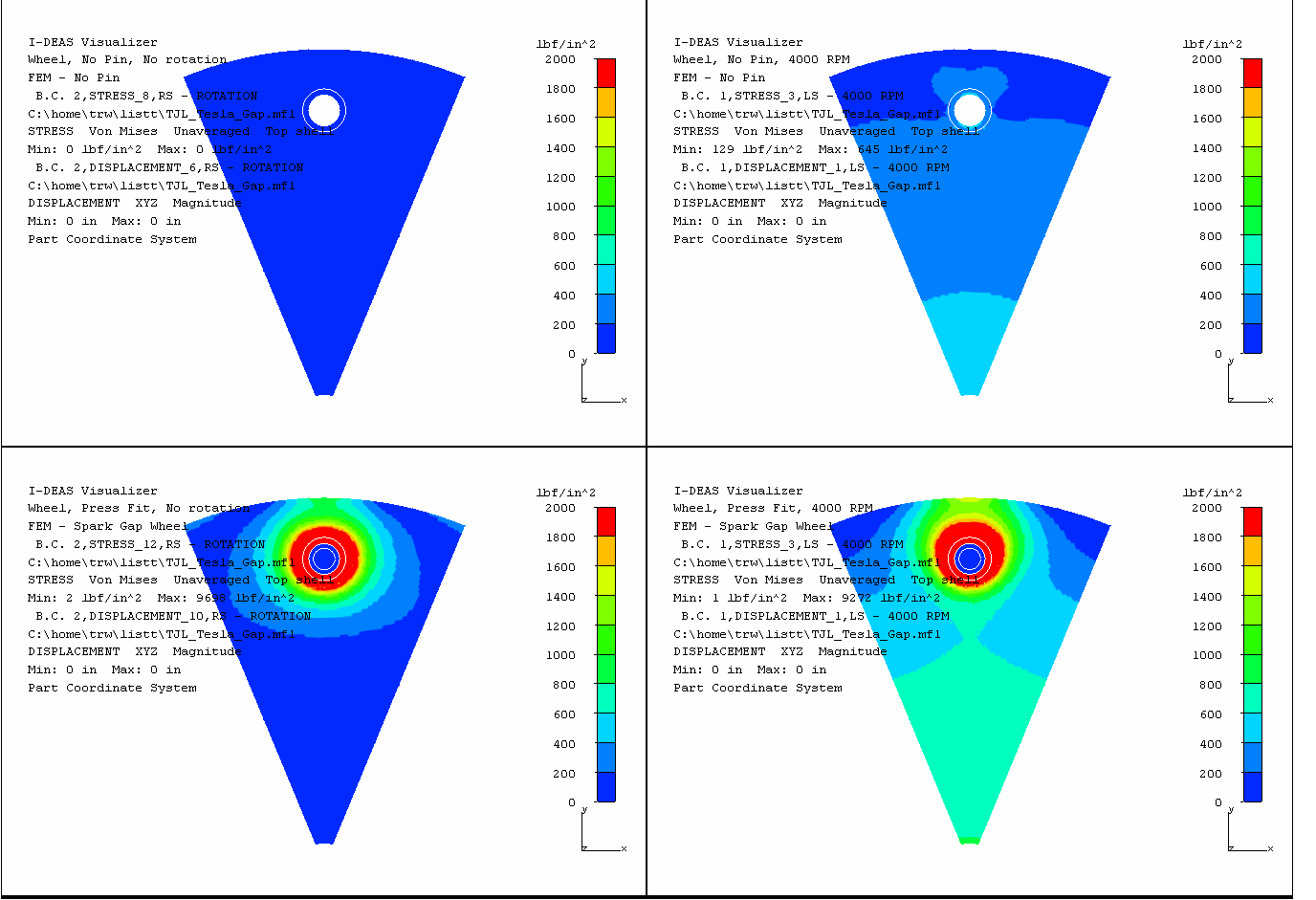

The top shot is the disk with the hole in it, at rest. The one next to it is spinning 4000rpm.

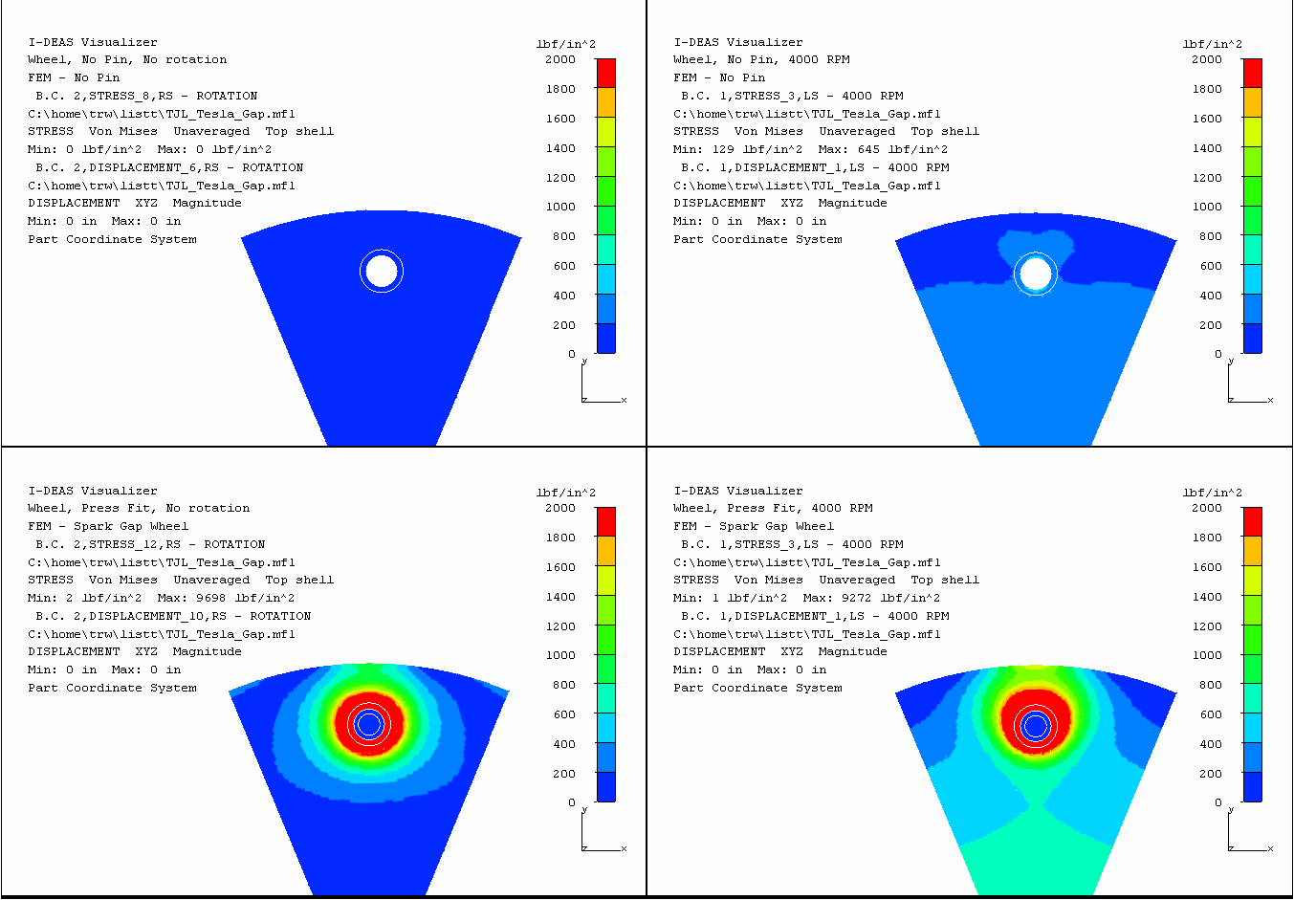

The next set starts with the 0.5" electrode press fit into a hole 0.0005" undersize hole, as Dr. Resonance recommends. On the left is the disc at rest and the right is spinning at speed.

The last set is stretched out and the scale increased.

You can see that with the press fit, there is over 9600 lbs of force holding the electrode in. The set screw added could hurt, help, or just not be needed. If someone can get me good data on the material properties for putting something into the side of the material, that can then be simulated. The mfg does not give that info (see data above), as that is not what it is designed for.

As far as the material giving out when my disk is at speed, I think there is plenty of safety margin, there is only 1600lbs of force pushing the electrode out and the material is good for 38,000 lbs/sq in. I feel comfortable proceeding now. I will still build a Lexan enclosure for it.

Interesting links:

http://www.theodoregray.com/PeriodicTable/

I have to give credit for the FEA that was done on this by my fellow coworker, Todd List.

Kevin